You’ve decided to add an electric floor heat system to your renovation. Only now, you need to know which of the following types is the best for you:

- Pre-formed electric heated floor mats

- Custom cut & turn mesh mats

- Electric heat cable systems

This post will cover the advantages and disadvantages of each heat system so you can make an educated decision. Once you figure out which system you want make sure you know what not to do when installing electrically heated floors.

OK, let’s get started!

Estimated reading time: 6 minutes

1. Pre-formed Electric Heated Floor Mats

Pre-formed electric heated floor mats are the easiest type of electric floor heating system to install. They are made of a sheet of plastic with a grid of heating wires embedded in it.

The most common way for you to buy these mats is to purchase standard sizes. For example, a heat mat may come 24 inches x 60 inches and you would install that on a section of your floor.

Further, you can purchase multiple sizes of these mats and connect them together in a way that fits your floor.

Custom-fit pre-formed heat mats

If you just can’t seem to find the configuration that you like with standard-sized mats some companies, like Nuheat, will offer custom mats sized exactly for your floor.

DIYTileGuy’s take:

They say that you can install these directly over a wood-framed subfloor. However, that’s news to me as it used to be that you needed cement board or Hardibacker down first.

Also, remember that any areas of the floor that do not have the mat would need an appropriate tile underlayment before installing any floor tile.

So, it really seems impractical to install these mats without installing cement board first then installing the mats over the backer board.

Advantages of Custom-fit pre-formed heat mats:

- Easy to install

- Can be used under a variety of flooring materials

Disadvantages of Custom-fit pre-formed heat mats:

- The size and shape of the heat mats can’t be modified

- Almost guaranteed to have cold spots where the mats don’t cover (unless it’s a custom-made mat)

- Assuming you install over cement board (see comments above) matching floor heights may be an issue, such as tile-to-hardwood or tile-to-carpet.

2. Custom Cut & Turn Mesh Mats

Custom cut and turn mesh mats are a type of electric floor heating system that is more flexible than pre-formed electric heat mats. The system consists of the heating wire attached to a mesh fabric that is all rolled up.

You then unroll the mat onto the floor and cut the mesh fabric (not the wire) wherever you want to turn the mat.

These rolls are sometimes self-adhesive and then you would install either thinset or self-leveling over the mat before installing the tile floor.

DIYTileGuy’s take:

Just like with the pre-formed heat mats above, it appears to me that they allow these mats to be installed directly over wood subfloors. Again, any area not covered by the mat would need an appropriate tile underlayment.

My recommendation is to install a tile backer board over your entire wood subfloor then install the mat where you desire.

Although, an option would be to install the mat and pour self-leveling underlayment over the entire floor. Doing this is perfectly fine as long as you use the appropriate self-leveler for the application.

Lastly, since Ditra-Heat came out, it isn’t easy to understand the advantages of this system.

Advantages of custom cut & turn mesh heat mats:

- More flexibility than pre-formed heat mats and you are able to heat all parts of the floor

Disadvantages of custom cut & turn mesh heat mats:

- Can be difficult to keep the mesh and bare wire in place before encasing it in mortar

- If installed over cement board (see comments above) floor heights may be an issue such as matching tile-to-hardwood or tile-to-carpet.

3. Electric Heat Cable Systems

Electric heat cable systems are the most versatile type of electric floor heating system. The wire comes rolled on a spool and you run the wire wherever you would like the floor to be heated.

Electric cable straps

The original way of holding down the loose heat cable was with floor heat straps (sometimes called cleats) made of aluminum or plastic.

You run the wire directly over the subfloor and the wire straps would serve the purpose of attaching the wire to the subfloor and provide consistent spacing.

The final step would be to pour self-leveling underlayment over the entire floor and encase the wires in the cementitious tile underlayment.

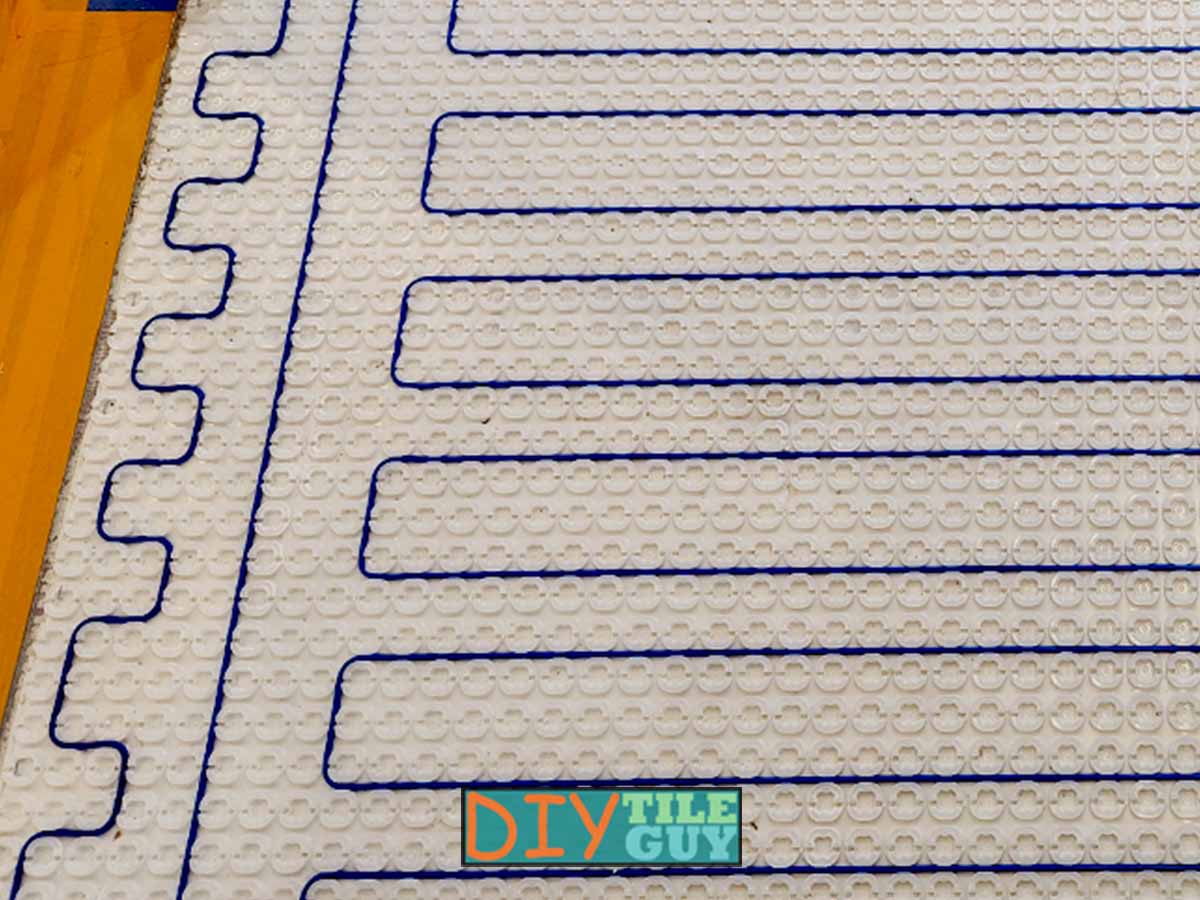

Uncoupling heat membranes

Since the invention of uncoupling heat membranes, such as Ditra-Heat mat and its lesser-known sibling Ditra-Heat-Duo, cable systems have exploded in popularity.

Now, it’s simple to run your heat cable wherever you like over your floor. Further, the membrane, by itself, is an appropriate tile underlayment so you run the underlayment over the whole floor and snap in the heat wire only where desired.

Finally, the whole system is about 1/4 inch thick so you should have no trouble with your tile-to-hardwood or tile-to-carpet transitions flushing out smoothly.

DIYTileGuy’s take

These types of systems that incorporate the uncoupling heat membrane with the heat wire are the best of all worlds. You get good heat coverage with a fairly simple and straightforward installation.

However, there is still a place for the wire & strap system. If you are going to self-level your floor then you just run the wires and pour your floor flat. You can install the tile directly over the self-leveling without a need for the uncoupling membrane.

Advantages:

- Simple to install

- Can heat every part of the floor

- Thickness of underlayment with heat wire doesn’t exceed 5/16th inch (8mm).

Disadvantages:

- Most expensive electric floor heat system (using the heat membrane)

Three Types of Electric Floor Heat Systems

There are three main types of electric floor heating systems:

- pre-formed electric heated floor mats

- cut-and-turn mesh heat mats

- electric heat cable systems.

Which system are you choosing and why?

Remember, no matter which system that you select, you’ll want to make sure to install concrete floor insulation before the floor heat if you are going over a concrete subfloor like a basement.