You want to tile your concrete floor. But there’s a problem. The concrete has cracks in it.

You know that if you tile right over the crack you soon will have a floor tile that’s cracked in the exact same spot. So what can you do to keep the tile from cracking?

Estimated reading time: 4 minutes

Do Uncoupling Membranes Really Prevent Cracked Tile Floors?

Maybe you’ve heard of a floor tile underlayment called uncoupling membranes. You know, products like Ditra or perhaps some of the uncoupling membrane competitors of Ditra.

These products are popular on DIY television and, today, many people are choosing, for example, Ditra over cement board. You may want to read my post on Ditra installation tips.

It’s possible that a store clerk or even a tile professional recommended uncoupling membranes as a way to prevent cracked tiles. Is this good advice?

Uncoupling membranes are designed for movement

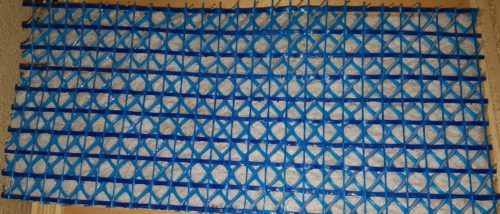

In this post, I link to an animation that shows how Ditra will allow the tile layer to move independently of the substrate.

It shows the air pockets created by the geometric shapes in the mat.

But, animation isn’t real life. So, just how much movement are we talking about?

Crack isolation membranes

There’s a classification in the tile industry called crack isolation membranes (CIS membranes). These membranes have undergone particular tests and met certain criteria.

They’ve been scientifically tested in what they can handle and how much they can handle. They will prevent some cracks from transferring through to your tile.

The membranes that have met these requirements are labeled as ANSI 118.12.

The Uncoupling Myth

Uncoupling membranes seem like they would prevent cracks also. But the fact is that most haven’t been (officially) tested as crack isolation membranes.

The powers that be in the tile industry want uncoupling membranes to be their own classification- separate from the CIS membranes. So this means that they will have their own tests.

Certainly uncoupling membranes will stop cracks, right?

Not necessarily. The uncoupling membranes have undergone private unofficial tests.

I’ve heard whispers of some that will pass the crack testing and others that won’t. But until these membranes are required to undergo industry testing we can’t be sure of how they will perform.

For example, Custom’s Redgard uncoupling membrane has been submitted for the A118.12 crack isolation test and passed.

So, not only is it considered an uncoupling membrane but is also categorized as a crack isolation membrane.

How to prevent cracked tile floors?

If you want to prevent cracks in concrete from transferring through to your tile floor the best products on the market are A118.12 crack isolation membranes.

These have been tested and have the highest performance.

Although uncoupling membranes are easily available and it seems like they would prevent cracked tile floors we can’t and shouldn’t assume that they will.

CIS membranes are still the top performers in the tile world.

So, the question isn’t “Do uncoupling membranes prevent cracks?” The question should be “Is my membrane an A118.12 crack isolation membrane?“